Features

- Stainless Steel Body complete with internal baffles

- Inlet Basket Screen

- Filters (from one to four dependent on the model)

- Inlet and Outlet Pipes 100DN

- Inlet and outlet Seals Clearseal

- Hinged Aluminium Covers

- Optional alarm and filter status detector

- Installation and operation manuals

- Product Quality Certification Quality Guarantee

Grease removal from kitchen wastewater is essential for the proper operation of sewage treatment plants, to prevent pipe blockages and to eliminate odour problems. The Bannow OGA Grease Trap is suitable for restaurants, hotels, golf courses, holiday resorts and leisure developments.

Bannow are specialists in all aspects of wastewater treatment which they supply to projects around the world.

Custom designed grease traps can be supplied to suit specific project requirements, such as increased retention times or higher peak flows.

Technical Features

Operation

The OGA combines the use of gravity separation, biochemical treatment and mechanical gap filtration to achieve a very high degree of treatment efficiency in the removal of FOGs.

In operation, the oily wastewater flows into the first compartment of the stainless steel body where FOGs rise to the liquid surface and larger particles settle to the base of the unit. The wastewaters then pass through a baffled arrangement into the second compartment which contains from one to four special filter units.

Filters

The special configuration of the filter units provides a very large surface area on which microbes form to become a living “membrane”. In order to discharge from the OGA unit, wastewaters require to pass through the microbe “membrane” where any remaining FOGs are effectively filtered out.

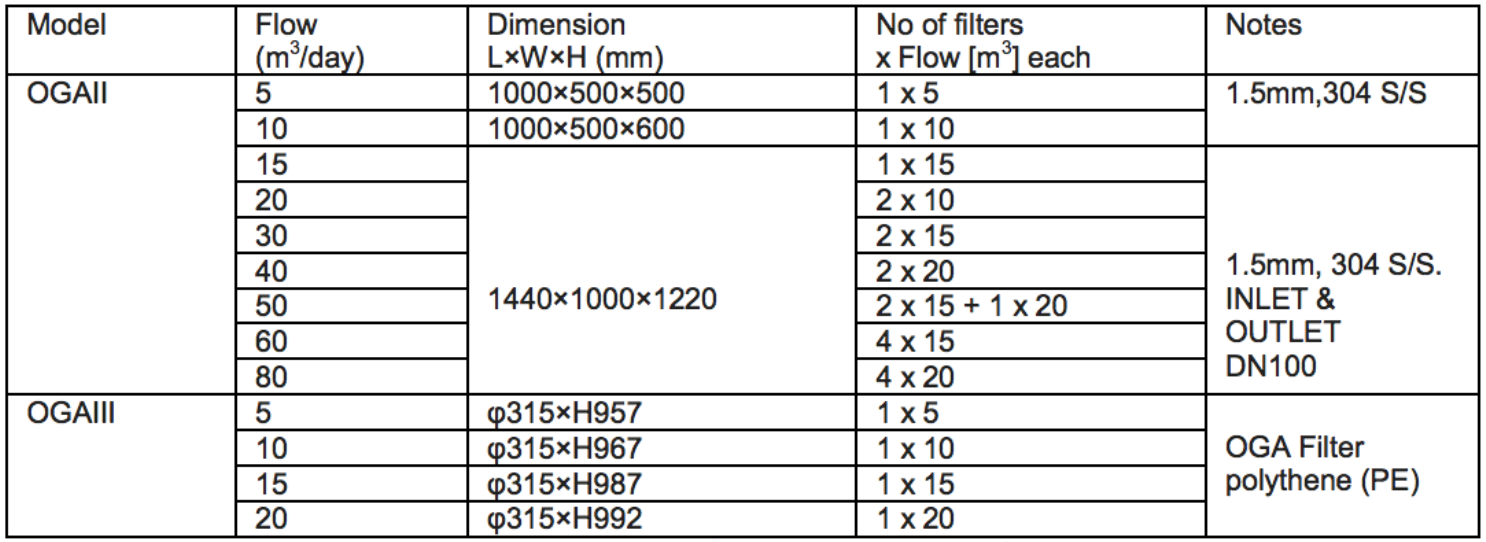

Specifications